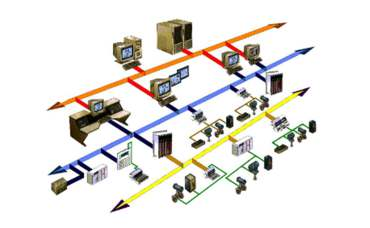

The overall solution for industrial automation of the whole plant is Huake Technology, which has been launched since the fourth industrial revolution (Industry 4.0), combining years of experience in industrial control automation and core products and system supplier platforms, from smart factories to intelligent production s solution.

Purpose:

Promote information integration, realize a new comprehensive automation model that integrates control, optimization, scheduling, management, and operation, and comprehensively improve the product quality, production capacity, multiplication level, and comprehensive competitiveness of the enterprise. The overall solution for industrial automation of the whole plant breaks through the layered concept of the traditional automation system. According to the concept of industrial 4.0 reform and development, unified data management, unified communication, unified platform, organically integrates and optimizes various independent and separated products and technologies, and makes full use of products. , The maximum function of the technical system, so as to produce the maximum benefit.

As an open overall solution, the overall industrial automation solution of the whole plant has excellent compatibility and openness, provides "one-stop" whole-process service, and protects the existing investment of users to the greatest extent.

●Advantages of the overall solution for industrial automation in the whole plant

Safety:

Utilize the highly reliable control system, high-quality detection and actuator products provided by the core suppliers to provide guarantee for the operation of the equipment, devices and assembly lines of the whole plant, and then carry out fault diagnosis and health maintenance for key devices.

low cost:

Years of experience in process control system projects and programmable logic control system projects, rich process assets, and a steady stream, Huake Technology improves the pass rate and transformation of factory products through reliable modeling technology, control technology and real-time optimization technology efficiency, and reduce energy consumption and raw material consumption, to achieve green production, energy saving and emission reduction.

high efficiency:

Through years of project experience, Huake Technology uses mature and reliable planning and scheduling and scientific scheduling, as well as process simulation training|services to improve equipment utilization and labor productivity. Improve overall competitiveness:

The overall solution comprehensively and deeply integrates the data and information of enterprises and factories, enabling safe, low-cost, and efficient production in remote factories, gradually increasing the value of enterprises and factories, and finally realizing the improvement of the comprehensive competitiveness of enterprises.

● DCS distributed control system

Huake Technology Co., Ltd. provides complete and mature large, medium and small DCS distributed control system and distributed control system solutions for petroleum, chemical, electric power and other industries. Hua Technology can use the systems of well-known DCS manufacturers at home and abroad to professionally design, program, and debug brand-new DCS systems for customers. Domestic ones include: Shanghai Xinhua, Zhejiang University Supcon, and Hollysys.

Foreign companies are: Honeywell, ABB, Siemens, Emerson, FOXBORO, Yokogawa, Rockwell.

● SCADA data acquisition and monitoring system

Huake Technology Co., Ltd. provides complete SCADA control system solutions for power systems, rail transit (railway, subway) systems, tunnel traffic systems, and gas transportation systems, including substation SCADA systems, subway SCADA systems, natural gas station SCADA systems, City gas SCADA system and other complete solutions. Professionally configure, design, program, and debug new SCADA systems for customers, and can also do upgrades, transformations, maintenance projects and services for original SCADA systems.

● PLC programmable logic control system

The PLC controller is the basic logic control unit and has a wide range of application fields. It replaces the traditional relay capacitor to realize logic control and sequence control. Such as injection molding machines, printing machines, staplers, combination machine tools, grinding machines, packaging production lines, electroplating lines, etc.

● RTU remote measurement and control terminal system

Huake Technology Co., Ltd. provides fully open and mature large, medium and small RTU control systems for oil, natural gas, water conservancy, electric power dispatching, bamboo government dispatching, subway rail transit, chain spectrum transportation and other industries. Huake Technology Co., Ltd. can use the software and hardware of well-known RTU manufacturers at home and abroad to professionally configure, design, program, and debug new RTU control systems for customers. .

Foreign ones include: ABB, SIXNETI, Bristol Control Wave (BB Emerson), SIMATIC (German Siemens), etc. Taiwan brands: MOXA Mosa, etc. Mainland brands: ECHO Security Control (Security Control Technology), etc.